Warré plans

Warré methods

Warré modifications

Warré precursors

Groups / Fora

Google

e-group

Biobees.com

forum

Abbé Warré's book

Beekeeping for All:

Roger Delon's Stable-Climate Hive (La Ruche Climatstable)

Roger Delon (1919-2007) was a commercial beekeeper in the Vosges/Jura region of France/Switzerland and is understood to have kept at least 600 hives in apiaries over a 120 km wide range. He was committed to the Warré box size, as his was only 5 mm higher, and to the principles of keeping in the brood nest warmth by adding new boxes underneath at the critical time. However, his hive and its management differs in several ways from Warré's as set out in the following table:

| Item | Warré (People's Hive) | Delon (Stable-Climate Hive) |

| floor | flat with 120 mm wide entrance notch; an alighting board | sloping down to front; rim; 45 degree alighting board; 300 mm wide entrance (full width); mesh floor for Varroa control |

| hive-body box | 300 x 300 x 210 mm box internal size; at least 20 mm thick walls; painted outside | 300 x 300 x 215 mm box internal size; 30 mm thick walls, dipped in creosote then linseed oil; painted outside |

| comb support | 8 top-bars with starter strips | 8 'semi-frames' with foundation; stainless steel rod round sides and bottoms of combs |

| comb spacing | template to space out top-bars while pinning them to rebate | castellated spacer strips |

| top-bar cover | cloth | cloth |

| quilt/crown board | 100 mm high vapour permeable 'quilt' containing moisture absorbing material, e.g. straw, sawdust, etc. | 30 mm high vapour impermeable insulated crown board |

| roof | mouse-proof gabled roof with ventilated loft | communal steel roof for up to 5 hives |

| stand | only one hive to a stand | communal, up to five hives |

| wintering | two boxes of comb | two or three boxes of comb; wrapped with black plastic sheet bound at the bottom |

| adding new boxes | underneath (except for sections) | underneath to start with; later on top in strong flows; and even in the middle of the brood nest |

| swarm control | artificial swarming with or without keeping brood of parent colony | aimed for 1-2 year-old queens; routinely made nucs to raise new queens, selected for non-swarmyness |

| race of bee | recommended Apis mellifera ligustica | recommended a locally adapted bee of a good breed |

| harvesting | draining crushed comb; tangential extractor in special cages | radial extractor; cut comb |

The thick walls, the insulated crownboard and the sloping floor with its full-width entrance to deal with any condensation suggest that Delon's variant of the People's Hive hive would be better suited to cold climates than the latter. His use of frames that do not prevent the nest from being hermetically sealed at the top, or from being bridged in places to the sides of the box, yet can be removed easily because of the single length of stainless steel reinforcings rod embedded in the comb at the sides and bottom, may have special value in countries where state law requires combs to be easily removable for inspection, e.g. USA and Canada.

The following composite photo is of an original Delon frame. It seems likely to have been a Mk.I version because the wire is not stainless steel and therefore has rusted. A detail shows the method of insertion of the wire into the top-bar. The hinge formed allows the metal 'U' to swing into a vertical plane. The bees would eventually secure the wire with propolis and comb (see below). The central slots, which were used for securing foundation, appear to have been cut from the underside with two incisions with a circular saw, because at the centre they do not align properly (see detail) and there is evidence of the work of the saw. (Thanks to Jean-François Dardenne for providing this sample which he received from Roger Delon in 1996.)

Above: example of Delon frame with drawn foundation

Below: Hervé Estival holding a Delon framed comb of bees

Evidence that bees build comb between the wire and the box wall

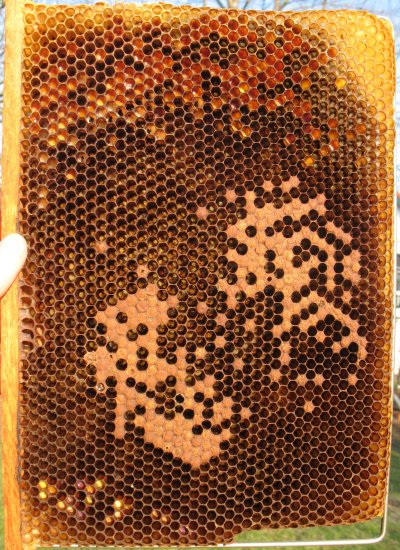

In the photo below, several combs, particularly at the top are attached to the box wall. The comb effectively embeds the wire frame. Source: http://www.pchelovod.info/index.php?act=Attach&type=post&id=56487

The following photo shows the frame wire embedded in comb on the right.

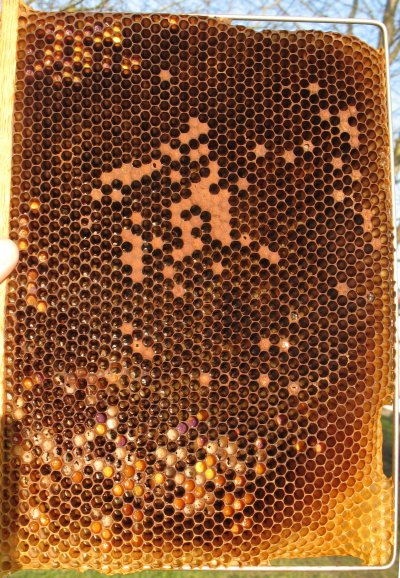

Evidence of building past the wire is less clear in the following two photos from Stephen Bird (Germany) who has given Delon frames a thorough trial in eight colonies.

He reports that the Delon frames are no easier to make than wooden frames. Here is a lightly edited quotation from his message to the former Warré beekeeping Yahoo e-Group on 28 March 2016:

"The bees will integrate the wire into their wax comb. If you have bent your wire accurately they will attach the frame to the side of the hive body just under the top bars (3-4cms) just like a Warre. There are two photos of the Delon frame in the photo album "Stephen".

Drilling accurate holes for the wire is difficult without a jig. Bending 3 mm stainless [steel] is easily done. The challenge is to do the drilling and bending without building in a twist, that [can become] a nightmare when you have a few frames bonded together with wax and reinforced with stainless [steel], and this totally defeats the object of the Delon frame. So, as stated, you need a bending jig and a drilling jig. It is also well worth the effort and expense of using a harder wood [for the top-bar]. All the holes and cuts produce quite a fragile frame when pine is used.

I have had better luck with my Delon hives lately and have six out of eight overwintered at this stage. If you need to remove a Delon frame you still need to cut it out, which often goes into honey -- not great if robbing is a threat. Once removed you can't lean it on a hive like a normal full wooden frame so one needs an empty hive body to put it in. The frame is surprisingly strong when built out and even seems to be a little flexible compared to a full wooden frame. It is easily handled and one is able to hold it at any angle without fear of damaging the comb. Some type of system to space the frames needs to be used, pins or castellated spacers.

I do like the the frame, but if I had to start again I would just buy full wooden frames. As with all frames, making a [lot of them] gets very trying. The Delon frames are just a pain to make well, and are very difficult to adjust if you didn't." (Stephen Bird, 28 March 2016)

For a method of fixing the stainless steel wire to the top-bars, see: http://jacky.apiculture.free.fr/nouveaux%20cadres.htm .

A Dadant 'growing down' or migrating into a Warré fitted with Delon frames and foundation. This process was started on 10 April 2008. Two weeks later there were mature queen cells in the Dadant and the Warré. The unit was used to make four colonies: 2 Dadant, 2 Warré (photo: Benoît Dupret).

Gus Mitchell's Delon-type frames

Download 17-page illustrated description of Roger Delon's Stable-Climate Hive (PDF, 2.2 Mb)

Slobodan Z. Jankovic (Serbia) has further developed the Delon version of the Warré into what he calls the 'Alpine Hive': http://pcela.rs/alpine_hive_1.htm. It has either Delon frames or wooden ones.

A variant of Delon's hive is also in use in Russia:

http://www.pchelhom.ru/index/0-6 (plansof

108 mm deep boxes) http://www.pchelhom.ru/index/0-4

(videos)

http://www.pchelhom.ru/index/la_climatstable_de_roger_delon/0-7

('Roger Delon's Stable-Climate Hive' in Russian)

http://www.ulei.150pr-rogovo.edusite.ru/

(note hive box lift)

and in the Ukraine:

http://www.stroyka-kupava.org.ua/index.php?option=com_content&view=article&id=15&Itemid=24

Most of the information on this page is taken from Beekeeping For All (Warré) and La Climatstable de Roger Delon.htm (Delon).