Warré plans

Warré methods

Warré modifications

Warré precursors

Groups / Fora

Google

e-group

Biobees.com

forum

Abbé Warré's book

Beekeeping for All:

Andy Collins, Scotland, November 2015

Construction

This is work in progress to find modifications that suit local conditions at this relatively northerly point in Europe.

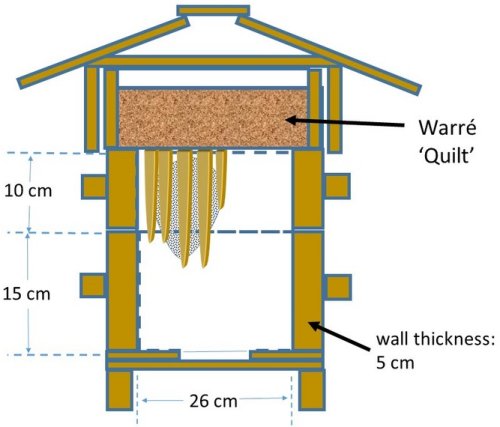

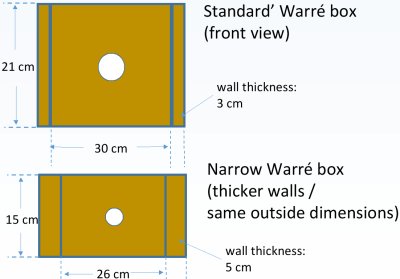

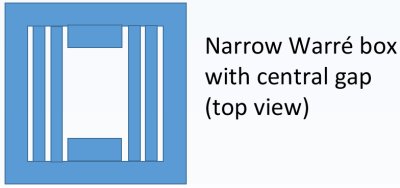

The external footprint of the box is fixed by the size of the existing Warré boxes: 360 x 360 mm.

The 50 mm thick walls diminishes the internal footprint to 260 x 260 mm.

Various box heights are used: 150 mm and 175 mm for the main hive body, and 100 mm for 'supers'.

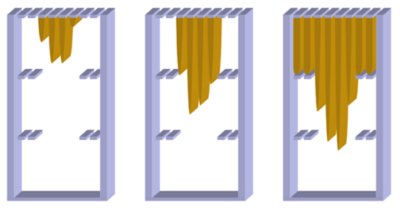

There are 4 top-bars per box, 2 at either side, leaving a gap down the middle for comb continuity. The bees then build down smoothly through the gap, filling out the whole box later. The bees generally build 7 combs instead of 8.

Adding a shallow super (with ladder comb) also seems to help minimise swarming if done just before the population goes into exponential growth mode.

The 150 mm box can hold up to 7 kg of recoverable honey, the super about 4.5 kg, generally suitable for presentation as cut comb.

The top-bar configuration is still under experimentation. It is doubtful whether the chicanes are really necessary for support. Some boxes without top-bars have been tried, using instead a pair of parallel canes perpendicular to the combs positioned half way down the box. That makes for a lot of comb to slice through on harvest though, so the configuration "2 + 2 top bars & central width restriction" will probably be used in future to make the harvest easier for the bees.

Data is still being collected, but comb progress is a lot smoother, and the modifications definitely make a harvest possible in hives which never seem to accumulate much more than 15 kg of stores. In those cases a smaller box allows a one box harvest which would not be possible in a standard Warré.

The continuity of the combs from one box to the next is similar to the Warré-like hives in Japan that are used for Apis cerana.

All other parts of the hive accord with Warré's design.

Below: progress of comb development

Harvesting

This is how 4 hives were harvested in 2015. Stage 1 (any time of day): check through the little windows that the top two boxes contain capped honey and that the overall hive weight indicates a genuine surplus. Run a wire carefully and slowly between the top two boxes, wedging them up by 4 mm at the corners as the wire traverses. Leaving the wedges in place, tape around the gap and leave the bees to clean up the cut comb for a day or so.

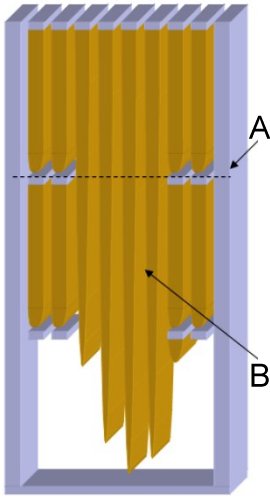

A -- level of cut

with wire; B -- risk of central comb collapse

A -- level of cut

with wire; B -- risk of central comb collapse

The hive is not fully opened at this stage and it doesn't seem too disruptive to the bees (no smoke needed). Comb collapse in the lower boxes hasn't been an issue so far. Sometimes the bees reattach comb between the boxes, which once caused a breakage in the top box when it was later lifted. So, as a precaution in, stage 2, starting about 4pm next day, slowly run through the wire again, before gently levering up the top box while simultaneously sliding in a sheet of Perspex (acrylic) to minimise nest scent loss and disturbance, and prevent mass escape of defensive guard bees. Then remove the top box to a distance of a few metres, and replace quilt on top of the Perspex then gently slide the Perspex out again. This is usually possible without smoke. Finally, gently coax the bees out of the harvested box and watch them fly back home. This this can take an hour or so.

Enquiries to Andy Collins: tandemcollins (at) blueyonder.co.uk